Exploring Window Replacement Roles in Japan: Skills and Techniques

Window replacement work in Japan focuses on removing old fittings, installing new units, and ensuring energy efficiency and safety standards. This article outlines typical responsibilities, tools used in the process, and practices followed by professionals in the field.

Window replacement work in Japan represents a specialized area of construction that requires specific technical knowledge and skills. This field involves understanding diverse architectural styles, from traditional wooden structures to modern commercial buildings. The work demands precision, attention to detail, and familiarity with Japan’s unique climate considerations and building standards. This informational overview explores the key aspects of window replacement techniques and practices used throughout Japan.

What Steps Are Involved in the Window Replacement Process?

The window replacement process follows a systematic approach that ensures proper fit and performance. Initial assessment involves measuring existing openings, evaluating structural integrity, and determining compatibility with new window systems. Removal of old windows requires careful handling to avoid damage to surrounding walls and trim. Installation begins with proper sealing and weatherproofing, followed by precise positioning and securing of the new window frame. Final steps include interior and exterior finishing, hardware installation, and comprehensive testing of operation and seal integrity.

What Tools and Materials Are Commonly Used in Replacement Work?

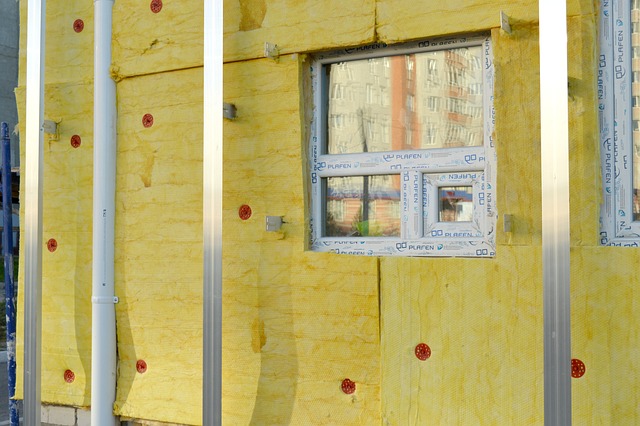

Professional window replacement utilizes specialized tools and high-quality materials suited to Japan’s climate conditions. Essential tools include precision measuring devices, reciprocating saws, pry bars, and leveling equipment. Installation materials encompass various sealants, weatherstripping, flashing, and insulation products designed for Japanese weather patterns. Window types range from traditional wooden frames to modern vinyl, aluminum, and composite materials. The work also requires appropriate hardware, including hinges, locks, and operating mechanisms that meet Japanese building standards and security requirements.

What Practices Support Energy Efficiency and Durability in Installations?

Energy-efficient window installation practices focus on minimizing thermal bridging and maximizing insulation performance. Proper air sealing techniques prevent drafts and moisture infiltration, which is crucial given Japan’s humid summers and cold winters. Installation of low-E glass and multi-pane systems helps reduce energy consumption for heating and cooling. Attention to proper drainage and ventilation prevents condensation issues common in Japan’s climate. Durability practices include using corrosion-resistant materials, implementing proper flashing techniques, and ensuring adequate structural support for the window system.

| Service Type | Typical Cost Range (JPY) | Duration |

|---|---|---|

| Single Window Replacement | 50,000 - 150,000 | 2-4 hours |

| Full House Window Upgrade | 500,000 - 2,000,000 | 3-7 days |

| Commercial Window Installation | 80,000 - 300,000 per unit | 4-8 hours |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Skill development in window replacement requires understanding of new materials, installation techniques, and building codes. Knowledge of traditional Japanese construction methods remains valuable, especially when working on older buildings or in historic districts. The integration of smart window technologies and automated systems represents an evolving aspect of the field as Japan embraces building automation and energy management systems.

Window replacement work in Japan must also consider seismic safety requirements, ensuring installations can withstand earthquake forces without compromising building integrity. This involves understanding proper anchoring techniques and selecting appropriate materials that maintain flexibility during seismic events. The field continues to evolve with advancing technology and changing environmental regulations, requiring ongoing learning and adaptation to new standards and practices.