Assembler Jobs in Japan – Production Line and Component Assembly Roles

Assembler jobs in Japan involve putting together parts, components, or products in factories, workshops, or production facilities. These roles require attention to detail, adherence to assembly instructions, and maintaining quality control standards. Suitable for individuals who can work efficiently and follow technical guidelines, the work may also include using hand tools, operating light machinery, and inspecting finished products. Many employers provide training on specific assembly processes, workplace safety, and equipment use.

What Daily Tasks Do Assembly Workers Perform?

Duties may include assembling parts, tightening fasteners, and testing products as core responsibilities in most assembly positions. Workers typically operate along production lines where they receive components and follow standardized procedures to create finished or semi-finished products. Quality control forms an integral part of these duties, requiring attention to detail and adherence to safety protocols.

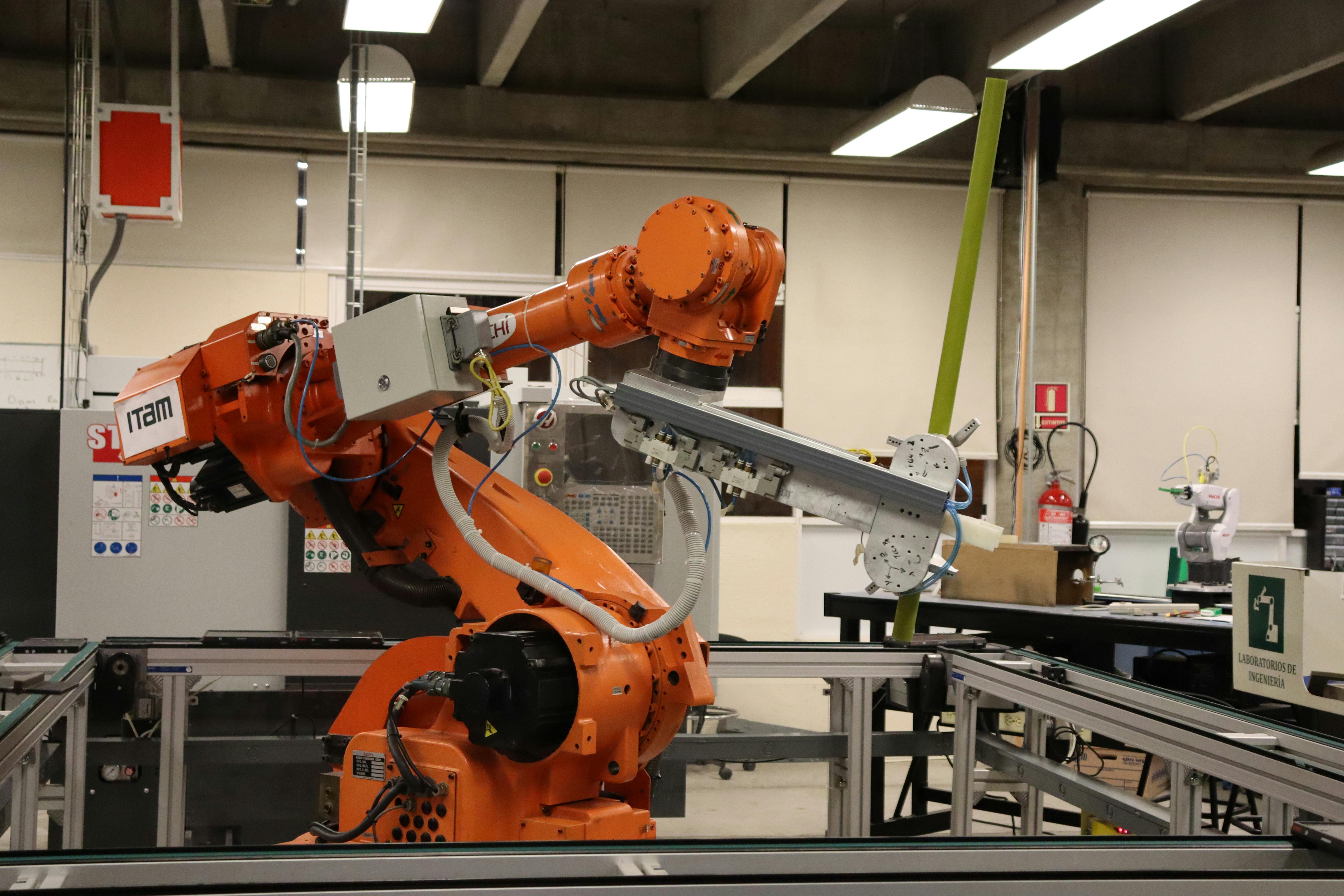

Assembly workers often use various hand tools, power tools, and specialized equipment depending on their specific production environment. The automotive industry, for example, requires workers to install components like electrical systems, interior panels, or mechanical parts. Electronics assembly involves handling delicate components and following precise specifications to ensure product functionality.

Do Assembly Positions Require Technical Skills?

Some roles require reading blueprints or technical diagrams, particularly in more specialized manufacturing environments. Workers in these positions must interpret technical documentation, understand assembly sequences, and follow detailed specifications. This skill set is especially valuable in industries producing complex machinery, precision instruments, or custom products.

Basic technical literacy has become increasingly important as manufacturing processes incorporate more digital elements. Many assembly positions now involve working with computerized systems, barcode scanners, and digital quality control interfaces. Training programs often provide these technical skills to new employees during their initial orientation period.

How Do Shift Patterns Affect Assembly Work?

Work schedules may involve day or night shifts depending on production needs and facility requirements. Many manufacturing plants operate continuously to maximize efficiency and meet production targets, creating opportunities for workers who prefer non-traditional hours. Night shift positions often offer additional compensation to attract workers willing to work during these hours.

Shift patterns can vary significantly between companies and industries. Some facilities operate on rotating shifts, while others maintain fixed schedules. Weekend work may be required during peak production periods or to fulfill urgent orders. Understanding these scheduling requirements helps prospective workers plan their work-life balance accordingly.

What Additional Responsibilities Do Assembly Workers Handle?

Staff may assist with packing and labeling finished goods as part of their expanded duties beyond core assembly tasks. This integration reflects the lean manufacturing principles adopted by many Japanese companies, where workers contribute to multiple stages of the production process. Cross-training in various roles increases job security and advancement opportunities.

Additional responsibilities might include inventory management, equipment maintenance, and workplace organization following the 5S methodology commonly used in Japanese manufacturing. Workers may also participate in continuous improvement initiatives, suggesting process enhancements and efficiency improvements based on their hands-on experience.

What Steps Are Involved in Securing Assembly Positions?

Application steps often include interviews, skills tests, and orientation programs designed to evaluate candidates and prepare them for their roles. The interview process typically assesses both technical capabilities and cultural fit within the organization. Many companies conduct practical assessments where candidates demonstrate their ability to perform basic assembly tasks or use relevant tools.

Skills tests may evaluate manual dexterity, attention to detail, and ability to follow instructions accurately. Some positions require specific certifications or training credentials, particularly those involving specialized equipment or safety-sensitive work environments. The orientation process familiarizes new employees with company policies, safety procedures, and production standards.

Conclusion

Assembly work in Japan offers diverse opportunities across multiple industries, each with distinct requirements and growth potential. These positions provide valuable experience in manufacturing processes while offering stable employment in the country’s robust industrial sector. Success in assembly roles depends on developing both technical skills and understanding workplace culture. This information serves as general guidance about the assembly job market in Japan and should not be interpreted as current job listings or active recruitment opportunities. Prospective workers should research current market conditions and specific employer requirements when seeking employment in this sector.