Assembler Jobs in Japan – Manufacturing and Production Roles

Assembler jobs in Japan may involve constructing products, checking quality, and following production guidelines in factory or workshop environments. Tasks can include fastening components, wiring, soldering, and operating machinery. Some roles are focused on electronics, while others cover larger equipment or automotive parts. Work schedules are usually tied to production cycles and safety standards, with teams following structured routines to ensure accuracy and efficiency. These positions highlight the importance of precision, teamwork, and adherence to workplace safety in maintaining steady production output.

Japan’s manufacturing industry has earned global recognition for quality, innovation, and efficiency. Assembly processes form a critical component in this industrial ecosystem, contributing to the production of electronics, vehicles, machinery, and consumer goods. This informational article explores the general characteristics of assembly work in the Japanese manufacturing sector, describing typical responsibilities, working environments, and industry practices.

What Duties Are Commonly Associated with Assembly Work?

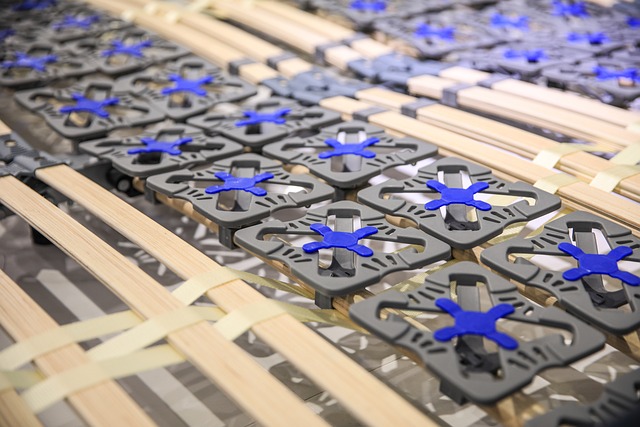

Assembly processes in Japanese manufacturing typically involve a range of technical tasks that contribute to product creation. These responsibilities commonly include fastening components using specialized tools, soldering electronic parts to circuit boards, and wiring assemblies according to detailed specifications. Many assembly processes require working with small, intricate parts that demand steady hands and excellent eyesight.

In electronics manufacturing contexts, assembly processes might involve connecting microchips to motherboards or putting together internal components for devices like smartphones, televisions, or industrial equipment. In automotive production, assembly work might focus on dashboard components, door mechanisms, or engine parts. Regardless of the specific product, Japanese manufacturing generally emphasizes precision and quality throughout the assembly process.

Quality verification is often integrated into assembly work, with checks performed using measuring tools and visual inspection to ensure components meet exact specifications. Documentation is another common element, with records kept of batch numbers, completion times, and any issues encountered during the assembly process.

How Do Assembly Processes Differ Across Japanese Industries?

The Japanese manufacturing sector encompasses diverse industries, each with specialized assembly requirements. Electronics assembly processes typically focus on circuit boards, semiconductors, and consumer electronics, requiring delicate handling of sensitive components and techniques like soldering and micro-assembly. These operations often take place in clean room environments with strict protocols to prevent contamination.

Machinery assembly typically involves larger components and may require more physical strength. These processes can include putting together industrial equipment, manufacturing machinery, or heavy components. Automotive assembly combines aspects of both electronics and machinery work, with operations ranging from dashboard assembly to engine component installation. Japan’s automotive sector is particularly known for its rigorous quality standards and efficient production methods.

Medical device manufacturing represents another specialized area, with precise assembly of instruments and equipment under strict regulatory guidelines. Consumer goods assembly spans everything from household appliances to toys and personal care products, each with unique assembly challenges and quality requirements.

What Are Typical Working Conditions in Japanese Manufacturing?

Working conditions in Japanese manufacturing are structured around production timelines and efficiency requirements. Shift patterns vary widely depending on the facility and production demands. Many plants operate on two or three-shift systems to maintain continuous production, with day, evening, and night shifts. Some facilities operate 24/7, particularly in industries with high demand or continuous production processes.

The physical environment typically features production lines or workstations arranged for maximum efficiency. Many Japanese manufacturers implement lean manufacturing principles, with workspaces designed to minimize waste and optimize workflow. Climate-controlled environments are common, especially in electronics manufacturing where temperature and humidity must be carefully regulated.

Japanese manufacturing facilities place strong emphasis on cleanliness and organization. The 5S methodology (Sort, Set in order, Shine, Standardize, and Sustain) originated in Japan and remains fundamental to workplace organization in many factories. Manufacturing personnel are expected to maintain clean, orderly workspaces and follow established procedures for tool management and material handling.

What Safety Protocols Exist in Japanese Manufacturing?

Safety is paramount in Japanese manufacturing environments, with comprehensive protocols designed to protect workers. Safety training is typically provided in manufacturing settings, with regular safety drills and refresher courses. Personal protective equipment (PPE) requirements vary by industry but commonly include items like safety glasses, gloves, ear protection, and appropriate footwear.

Structured safety routines include pre-shift equipment checks, proper tool handling procedures, and ergonomic guidelines to prevent repetitive strain injuries. Many facilities implement visual management systems with color-coded zones, safety signage, and clearly marked emergency routes. Regular safety audits and inspections help maintain high standards and identify potential hazards before incidents occur.

Japanese manufacturing culture emphasizes collective responsibility for safety, with encouragement to report potential hazards and suggest improvements to safety procedures. Many facilities use safety circle meetings where teams discuss recent incidents, near-misses, and preventive measures. This collaborative approach to safety helps maintain Japan’s relatively strong industrial safety record despite the inherent risks in manufacturing environments.

What Qualifications Are Typically Sought in Manufacturing?

Manufacturing in Japan typically involves a combination of technical skills and personal attributes. Technical qualifications may include basic mechanical aptitude, understanding of assembly diagrams, and ability to use hand tools and measuring instruments. Educational backgrounds vary across the sector, with some manufacturing roles requiring high school education while more specialized functions may involve vocational training or technical certifications.

Skills assessments are common in the manufacturing sector. These evaluations might examine manual dexterity, ability to follow detailed instructions, and basic quality inspection capabilities. Some manufacturing environments require specific technical knowledge, such as basic electronics understanding or blueprint reading.

Health considerations are relevant to manufacturing work. Good eyesight is important for detailed assembly tasks, while physical stamina may be necessary for positions requiring standing for extended periods. Some environments may have specific health considerations, such as the ability to work with certain materials or in particular environmental conditions.

Japanese language proficiency is generally valuable in manufacturing contexts, though requirements vary. Technical training programs focused on manufacturing skills provide foundations for relevant capabilities. Understanding of quality control principles, particularly Japan’s approach to continuous improvement (kaizen), is also beneficial in manufacturing environments.

Understanding Compensation in Japanese Manufacturing

Compensation structures in Japanese manufacturing vary based on factors including location, industry specialization, company size, and shift patterns. Urban areas like Tokyo, Osaka, and Nagoya generally have different wage scales than rural regions. Night shifts and weekend work are often associated with premium pay rates in manufacturing environments.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The manufacturing sector includes various professional development paths. These might include technical specialization, quality control roles, or supervisory positions. Many manufacturing companies provide internal training programs to support skill enhancement. Cross-training across different assembly processes is increasingly valued, allowing for versatility across production areas.

Japanese manufacturing continues to evolve with technological advancements, creating changing skill requirements. While automation has transformed some aspects of manufacturing, skilled human workers remain essential for complex, precision-oriented tasks that automation cannot yet reliably perform. The manufacturing sector continues to value individuals who combine traditional skills with technological adaptability.

For those interested in understanding more about Japan’s manufacturing sector, industry associations, economic reports, and educational institutions offer resources about trends, practices, and developments in this important component of Japan’s industrial landscape. These sources can provide deeper insight into the manufacturing environment and its role in Japan’s broader economy.

This article provides general information about assembly work in Japanese manufacturing and does not represent specific job listings or employment opportunities. Those interested in actual employment should consult relevant job boards, recruitment agencies, or company career pages for current openings.